Address

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

Phone/Fax

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Work time

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed

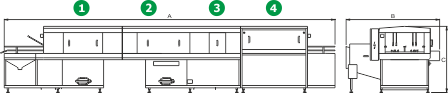

Washing machine for plastic crates, modular type, capacity 500 to 2000 pcs/h

Stainless steel construction, AISI 304 (1.4301). Designed for washing plastic crates. Pass through type. Crates are fed and transferred through the machine by a steel chain conveyor in a one row or in two rows. Crates dimensions: 600x400x150/350 mm. In the version with two rows a higher capacity is achieved at shorter length of the machine. There are several separate modules successively connected in the machine:

1. Pre-washing module.

2. Module for main washing.

3. Disinfection and rinsing module.

4. Module for blowing with air.

Machines are manufactured with electrical or steam heating of the washing water. The water being used is transferred to the preceding module due to optimal usage of electricity and detergents being invested. The control is detached in a moved out panel, mounted on an appropriate place near the machine.

Options: an aspiration hood with / without a fan, automatic injection of disinfectant in the rinsing collector.

Technical data:

Crates dimensions: 600x400x150/300 mm

Water inlet: 1”, 4-6 bar – reservoir fill up

¾”, 4-6 bar - 45-50°C rinsing water

If disinfection is required, the temperature of rinsing water should be 80-85°С.

Water outlet: 2”

Electrical connection: 400V/50Hz

Steam heating:

Steam connection: 1”, 3 bar, 130°C

Steam consumption: 100-120 kg/h

Compressed air connection: ¼”, 4-6 bar

| Art. № |

Capacity | Type | AxBxC (mm) |

Water |

Power |

|---|---|---|---|---|---|

| 05.11.911.000 | up to 1000 | one row | 9300х1450x1700 | electrical | 74,7 |

| 05.11.921.000 | up to 1000 | one row | 9300х1450x1700 | steam | 29,7 |

| 05.16.911.000 | up to 1000 | two rows | 8400х1580x1700 | electrical | 86,5 |

| 05.16.921.000 | up to 1000 | two rows | 8400х1580x1700 | steam | 41,5 |

Questionnaire about washing machine you can fill here or you can download the pdf file, fill the nessesary information, and send it back by e-mail. ![]()

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed