Address

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

Phone/Fax

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Work time

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed

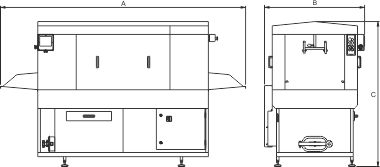

Washing machine for inventory

Stainless steel construction, AISI 304 (1.4301); This is an universal machine for washing containers, pieces and wrapping with different dimensions; maximum dimension of the containers being washed: 600 × 400 × 450 mm; Pass through type with width of passage 630 mm.; Containers are transported through the different zones of the machine by a stainless steel mesh belt conveyor; Adjustable belt speed; Specially profiled guides hold and conduct the containers. For this purpose the customer provides in advance a sample of the containers or a detailed drawing with weight; Removable side covers for easy cleaning; Guiding furrows for taking the containers in and out; A revision cover of the reservoir for easy cleaning;

Options: Washing agent dispenser; Touch screen control; Automatic filling and emptying of the reservoir;

There are two sections in the machine – washing and rinsing. The containers are poured with circulating cleaning solution heated up to 50-55°C in the cleaning section. The temperature is controlled by a thermo regulator. The solution is kept in the reservoir of the machine. The cleaning solution is evenly distributed over the containers through a system of nozzles with adjustable direction. The nozzles under the containers are mobile and make reciprocating moves during the washing process for better cleaning performance. The washing solution is circulating and prior to flowing back in the reservoir it is filtered through a sieve drawer which can be easily removed for cleaning. After the washing is over, the containers go through the rinsing section. There, they are rinsed with clean hot water /80-85°С/. This water is supplied by the water main of the customer. The rinsing water goes into the reservoir for main cleaning and refreshes the cleaning solution while the filth is led away through the overflow drain of the reservoir. The machine is manufactured with electrical or steam heating of water in the reservoir.

Technical data

Capacity: up to 150 cont/h; (depending of the contamination and the size of the containers)

Water inlet: 1”, 4-6 bar

Water outlet: 1 ½”

Electrical connection: 400 V, 50 Hz

Steam connection: 1/2”, 3 bar, 130°C

Steam consumption: 50…80 kg/h

Compressed air connection: ¼”, 4…6 bar (steam heating)

| Art. No | AxBxC (mm) | Water heating | Power installed, kW |

|---|---|---|---|

| 05.91.310.000 | 2900х1100x1700 | electrical | 15,4 |

| 05.91.320.000 | 2900х1100x1700 | steam | 3,4 |

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed