Address

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

Phone/Fax

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Work time

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed

Cutting and selection lines for red meat with modular and smooth impregnated belts made of artificial material

Finds application in cutting and selection of pork and veal;

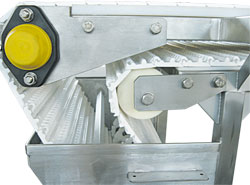

Body and leading elements made of stainless steel;

Driving of belt conveyors can be implemented with directly connected gear motor, gear motor with transmission or with a motor built in the driving roller (roller-motor);

Driving reduce motor gear groups are well protected by stainless profiled covers;

Implementing the equipment with a motor roller optimizes the construction, makes the maintenance easier and facilitates hygiene control;

For complex projects of rough cutting in vertical position, the lines are equipped with tables and chutes having different sizes and configurations;

Special roller tables or belt conveyors for distributing and forwarding of the main fractions are mounted to the lines referring to horizontal rough cutting with stationary disk saw or band saw;

Tables for fine cutting are manufactured according to the customer's requirements, special features of the cutting process and the possibilities of optimal division of meat pieces;

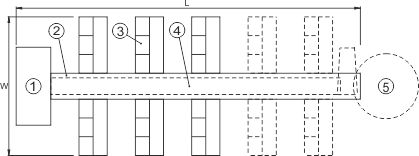

Some of the applicable schemes of implementation are shown on figure 1.

1.Main fractions transportation;

2.Portions transportation;

3.Bones transportation;

4.Crates full of portions and bones transportation;

5.Clean wrapping transportation;

* All dimensions shown on the figure are valid if Е2 crates are used.

Depending on the conveyor project the following conveyors can be manufactured: belt and roller conveyors for transporting of meat pieces and crates with meat pieces, conveyors for bones discharging, conveyors for clean crates supply etc;

Selected portions can be put in to crates, placed at each working place or can be put on special rotating tables for sorting at the end of the line;

For optimizing the cutting process, special schemes for quantity and quality assessment of the products in real time can be realized;

According to these schemes all products (portions, bones, trimming etc.) go through an ID point, situated on the line's exit;

Belt conveyors can be manufactured with a mechanical or pneumatic system for releasing and lifting of the belt in order to achieve easier cleaning of the equipment;

For washing the conveyor belt during operation, special washing systems can be installed in to the conveyors.

For washing the conveyor belt during operation, special washing systems can be installed in to the conveyors.

Manufacture of standard cutting lines includes:

1. A table for rough deboning; 1800х800х850mm, shelf, d=20mm

2. Belt conveyor for meat: В=600mm H=900mm, with mechanical system for lifting the belt for cleaning afterwards;

3. A table for fine deboning with three positions for selecting meat;

4. Belt conveyor for discharging of bones, B = 400 mm.

Adjustable speed of the belt: 3 - 9 m / min;

Actuation by a directly connected reduction gear motor;

Available options to the standard manufacture of cutting lines:

5. Rotating table located at the end of the belt conveyor for sorting the deboned meat;

Washing station for the belt of the meat conveyor.

| Art. № | № of working positions | Belt for the bones | Overall dimensions LxWxH (mm) |

|---|---|---|---|

| 22.10.110.200 | 6 | no | 5300х3340х900 |

| 22.10.210.200 | 8 | no | 6700х3340х900 |

| 22.10.310.200 | 10 | no | 8100х3340х900 |

| 22.11.110.200 | 6 | yes | 6000х3340х1700 |

| 22.11.210.200 | 8 | yes | 7400х3340х1700 |

| 22.11.310.200 | 10 | yes | 8800х3340х1700 |

Modifications of the standard manufacture of cutting lines: table for fine deboning with two positions for selecting of meat; Positioning of the tables for fine deboning - parallel with the belt conveyor; Actuation of the belt conveyor – with roller drives. Pneumatic system for lifting the belt for washing after work.

Questionnaire about configuration of a cutting line - please download the pdf file, fill the nessesary information, and send it back by e-mail. ![]()

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed