Address

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

Phone/Fax

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Work time

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed

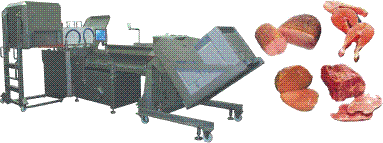

HighTech Injection centres

The IR 17 model is the entry-level model for businesses. The IR 56 meets strict industrial requirements and the IR 112 is an adaptable high-performance machine for up to 7000 kg/h.

The injection centres cure cooked and raw cured products to a high level of accuracy (0.5 % variance). Thanks to the savings achieved via the unique handling of the injection liquid, users recover the cost of the machine within a short period of time.

To ensure a uniform injection result, high operating pressures have to be applied to compact meat structures so that fluid can be stored between the fibres.

To ensure that equal quantities of brine are injected into the bones and other parts of the meat, the brine supply to a needle is automatically switched off as soon as the needle encounters a bone.

Equipment:

- Process-diagnostic system

- Variable process speeds

- Welded machine construction

- Cleaning assistant

- Touch-PC control

- Feed system

- Single needle control

- Centrifugal pump

- Softer

- CE und GS test certificate.

HighTech Tumblers

The HighTech Tumbler is a real all-rounder offering chilled tumbling, mixing and marinating. It performs each of these tasks to optimum effect without concentrating on one application at the expense of another. On the contrary, the technical equipment for tumbling is also used for mixing, for example.

The system uses a rotating arm in the tank and is still the subject of much discussion today since it is often criticised as being too aggressive for the production of cooked ham.

The MKR 150 machine type processes around 110 kg of boiled ham in a single batch, which means that it meets the requirements of smaller business. A butcher with higher processing requirements is best served by the MKR 220, which has the same footprint but offers a batch volume of 160 kg.

The MKR 300 and MKR 600 models are available for greater volumes. These also feature an automatic feed system.

Equipment:

- 100% container insulation

- Swivel locking lid

- Swivelling the container

- Direct cooling system

- Sterilisation system 90%

- Computer control Touch PC

- Bayonet arm attachment

- Scraper-pressure attachment

- CE/GS test certificate

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

Our company produces machines and equipment for the food industry; hygienic equipment made of stainless steel for the food industry and the pharmacy, for the meat industry we deliver, install and guarantee the service of the machines from leading companies in this branch.

str.12, № 1, Vedrare, Karlovo,

ZIP code: 4364

GPS coordinates: 42.57898, 24.87561

(+359) 335 99915

(+359) 335 99913

bonner@dir.bg

info@bonner-bg.com

Mon - Fri: 08:00 - 16:45

Sat - Sun: closed