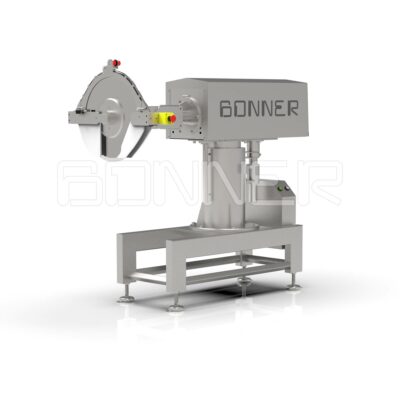

Description

Finds application in cutting and selection of pork and veal. Body and leading elements made of stainless steel AISI 304 (1.4301). Easy maintenance and good reliability. Excellent hygiene during equipment operation thanks to the stainless metal belt and body construction made of tightly welded stainless profiles. According to the task different types of tables or chutes for rough and fine cutting can be added to the main belt conveyor. The tables for fine cutting can be situated parallel with the line or sideways. They can be implemented with or without holders for crates. Over the main belt conveyor additional conveyors for taking away different pieces, bones or for supply of clean wrapping, can be added. At the end of the line a rotating table for sorting, a table for cutting or a chute can be mounted. With built-in system for washing the metal stainless steel belt during operation process.

Technical data:

Width of the metal belt: 600 – 1000 mm

Belt thickness: max. 1 mm

Max. loading capacity: up to 120 kg/m

Water connection: 1/2”, min. 4 bar

Voltage: 400 V/50 Hz

Power installed: 1,1 – 2 kW

Speed: constant or with a possibility of regulation within the range of 3 – 9 m/min.