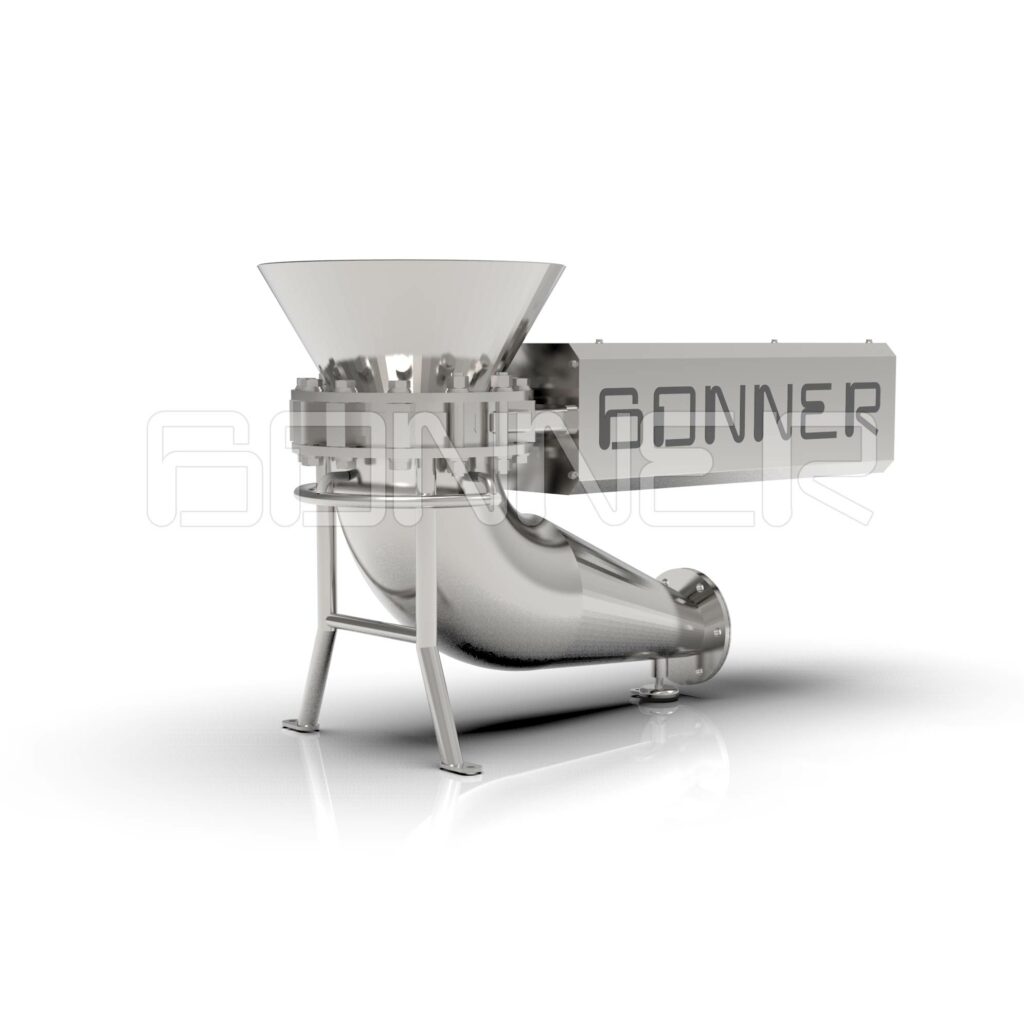

Description

• For transportation of abdominal organs, bristle, stomach content, crashed bones and other products from slaughter line to processing premises;

• A solution with the following advantages:

– improves hygiene of the slaughtering process;

– takes away all waste and sub-products from the working area fast;

– leads to optimization of the production process and technological flows, reduces the traffic from transport carts;

– easy maintenance, cleaning and washing;

– small consumption of energy;

• Made of stainless steel;

• Implementation depending on the capacity and technological needs:

– capacity of the receiving hoppers: 60…300 l;

– diameter the receiving hopper flap: Ø 200 … Ø 400 mm;

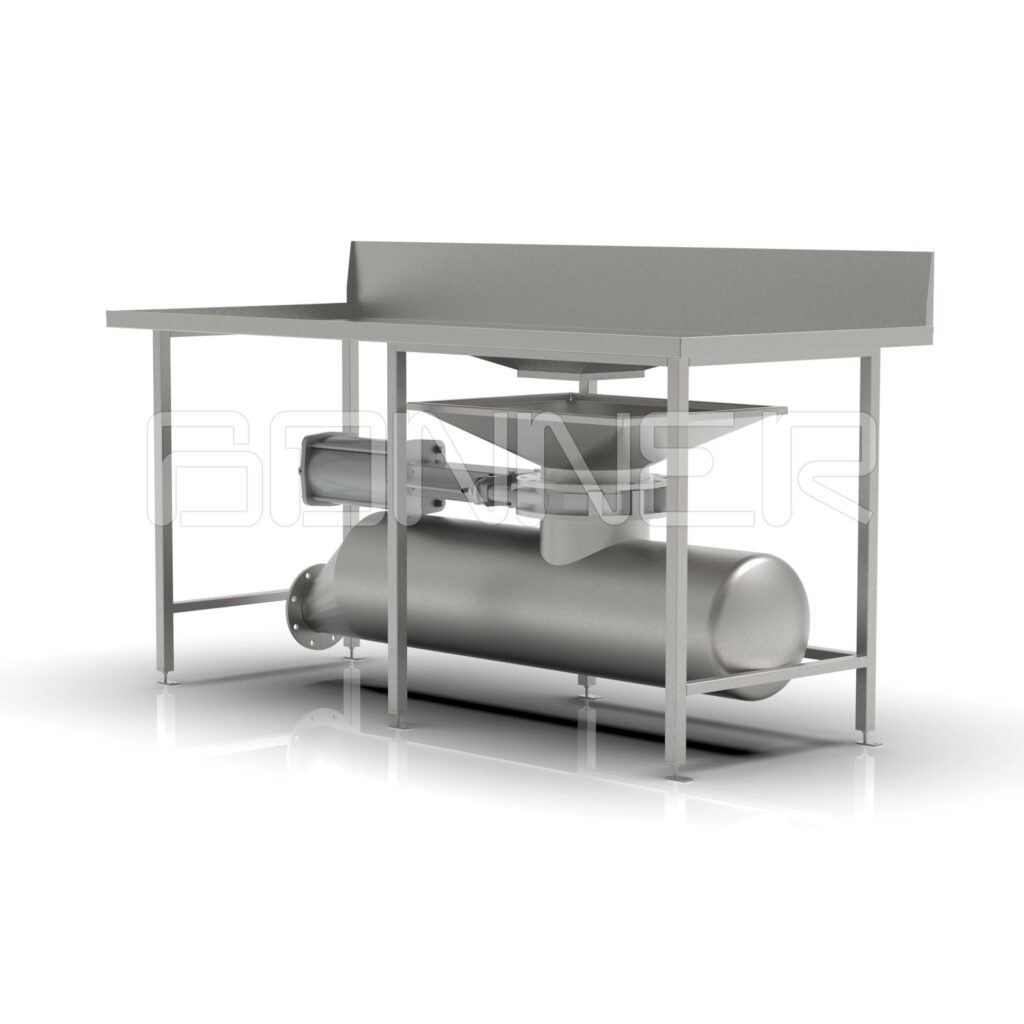

• Integration in working tables, receiving chutes and other equipment;

• System control: manual, semiautomatic or automatic;