Description

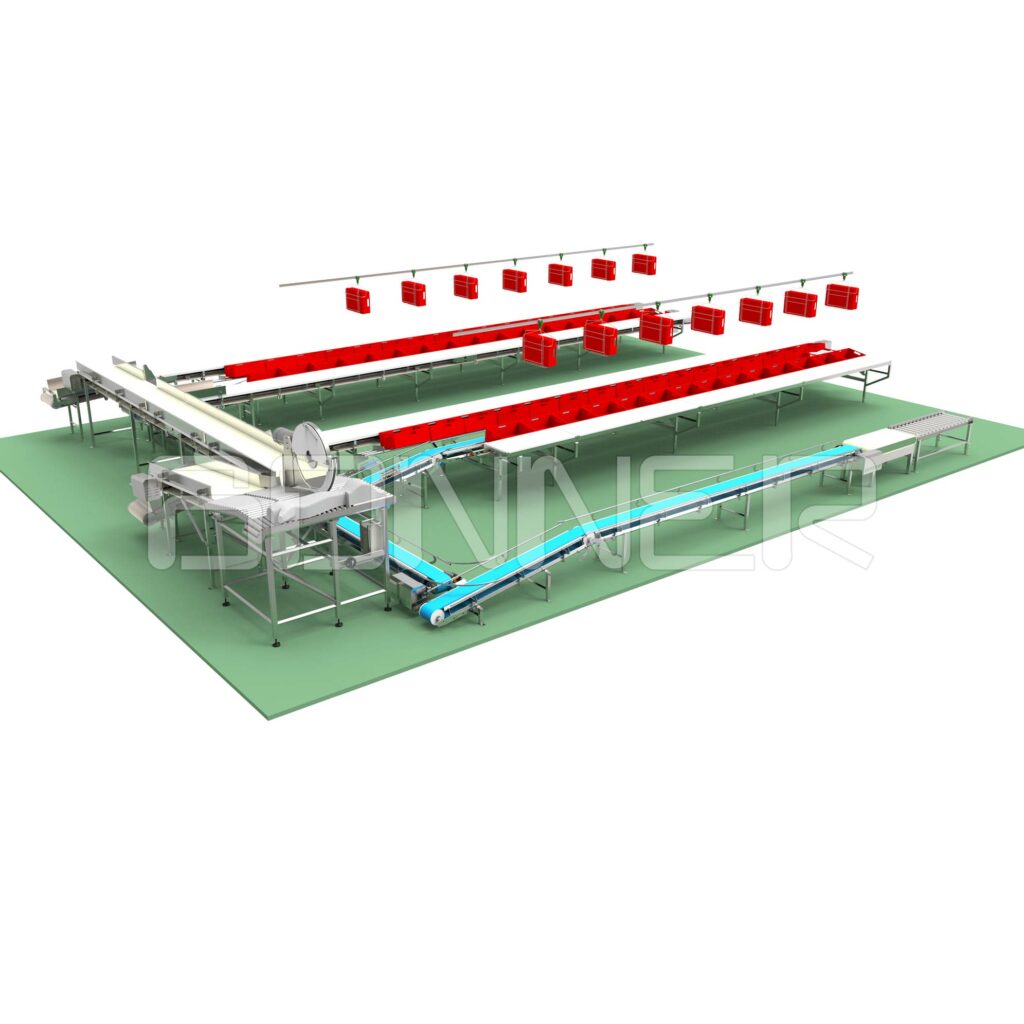

Technological lines with a high degree of mechanization for the separate technological processes. Pork halves are fed to the rough cutting zone by

conveyor systems or elevators with continuous flow. Rough cutting of pork halves is done in horizontal position through specialized systems of belt conveyors and integrated in them disk saws. Halves directing during cutting is done manually thanks to light markers determining the line of cutting. After cutting of the main fractions (rounds, shoulders, cutlets and breasts) they are automatically distributed towards the lines for additional processing and fine cutting.

Fine cutting process is done meanwhile directly on the transporting belts. This process requires extremely high specialization from the operator.

According to the cutting requirements for some of the operations are implemented stationary working places near the main lines. For the processing of additional products (heads, legs, trimmings etc.) are manufactured cutting lines having a configuration conformable to the peculiarities of each product. All technological machines and equipment necessary for special operations (skinning, ribs removing, shaping

etc.) can be integrated into the lines.

The following equipment can be implemented as an addition to these lines:

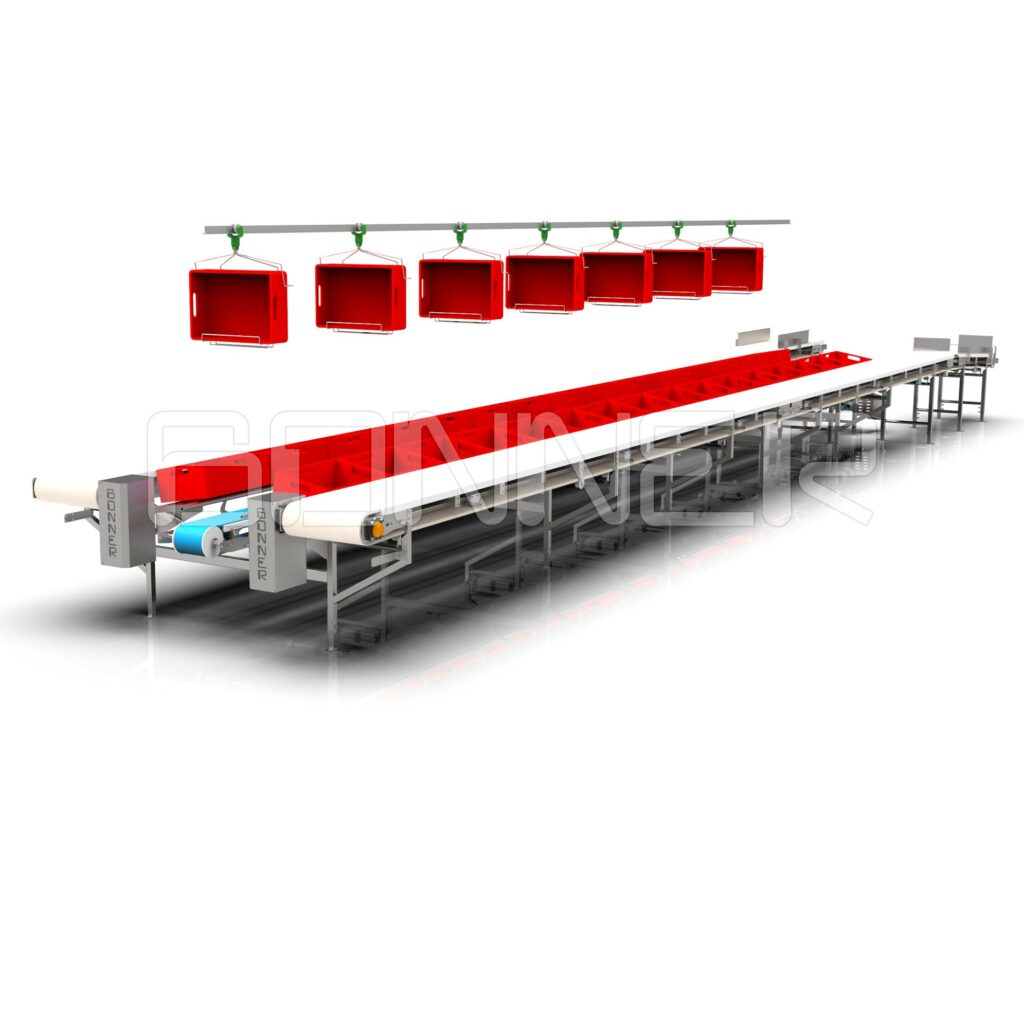

- Belt transporting systems for ready products (meat in trays, crates, cardboard boxes etc.)

- Belt conveyor systems for transporting of bones and residues to the storage and processing zones.

- Systems for clean wrapping supply: horizontal belt conveyors or suspended chain conveyors.

- Systems for transporting the released hooks to the washing and storage premises.

- Non-mechanized (sloped) roller depots for readyproduction storage in crates, cardboard boxes and pallets.