Description

Stainless steel construction, AISI 304 (1.4301); Designed for washing containers and small pieces; Chamber type; Programmable control; Parts and pieces are placed in a mesh basket with diameter Ø 980mm, which rotates during the two stages of the working cycle;

First stage – main washing: a stationary nozzles collector sprays the parts with circulation cleaning solution, heated to preliminary adjusted temperature and regulated by a controller. Prior to flow back in the reservoir, the cleaning solution is filtered through two sieves which are easy to be removed for cleaning.

Second stage – rinsing: a stationary collector with special low consumption nozzles sprays the parts with clean hot water /85°C/. This water is fed from the water installation of the customer. Water coming from the rinsing process goes to the main tank, refreshing the washing solution, keeping its temperature and leading dirt away in the overflow drain of the reservoir. Duration of both stages is determined by contamination of the pieces and can be adjusted from the electrical panel;

Option: Washing agent dispenser;

Technical data

Fill up tank water inlet: R 1”

Rinsing water inlet: ½”, 3 bar, 80…85°C

Water outlet: 1 ½”

Electrical connection: 400 V/50 Hz;

Steam inlet: 1”, 3bar, 130°C;

Compressed air inlet : ¼” 3…6 bar;

Height of pieces: max. 400 mm;

Weight of pieces: max 25 kg;

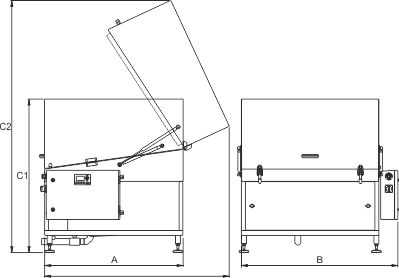

| Art.№ | AxBxC1/C2,mm | Water heating | Power installed, kW |

|---|---|---|---|

| 05.98.010.000 | 1130х1275×1250/2053 | electrical | 14,4 |

| 05.98.020.000 | 1130х1275×1250/2053 | steam | 2,4 |